“Optimizing Industrial Control with PLCs and Switches/Relays”

Programmable Logic Controllers (PLCs) are widely used in industrial control systems to automate processes and improve efficiency. They are particularly useful in applications where there are many switches and relays that need to be controlled in a precise and consistent manner. The use of PLCs with switches and relays and how they can be used […]

Programmable Logic Controllers (PLCs) are widely used in industrial control systems to automate processes and improve efficiency.

They are particularly useful in applications where there are many switches and relays that need to be controlled in a precise and consistent manner.

The use of PLCs with switches and relays and how they can be used together to improve the performance of industrial control systems.

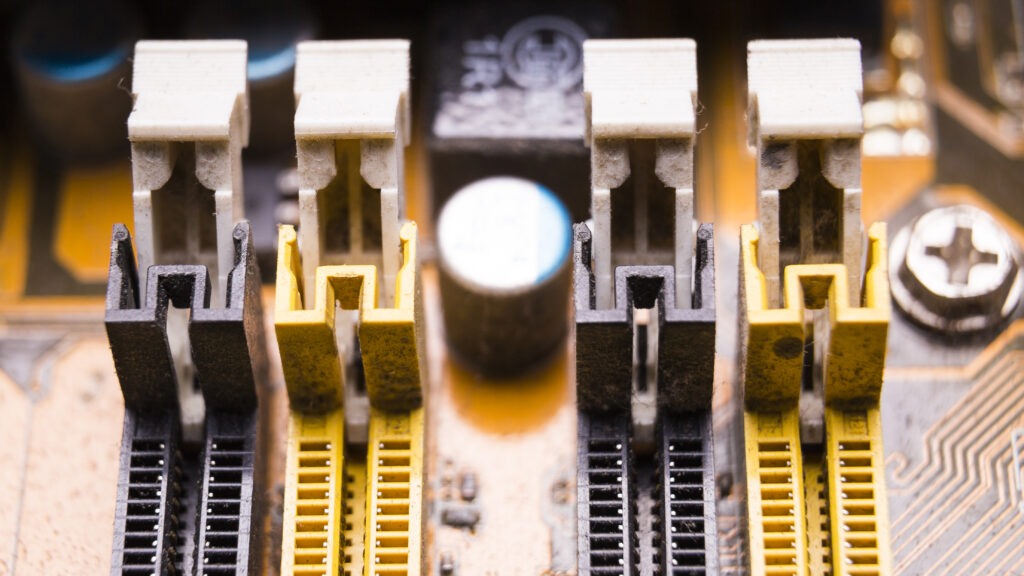

Switches and relays are devices that are used to control electrical circuits. They are commonly used in industrial control systems to turn on and off motors, lights, and other equipment. However, controlling many switches and relays manually can be time-consuming and prone to errors. This is where PLCs come in.

PLCs are small, programmable computers that are designed to control industrial processes. They can be programmed to perform a wide range of tasks, including controlling switches and relays. PLCs can be programmed to turn on and off switches and relays in a specific sequence, ensuring that the process is running smoothly and efficiently.

One of the main advantages of using PLCs with switches and relays is that they can be programmed to perform specific tasks without the need for manual intervention.

This reduces the risk of human error and improves the consistency of the process. PLCs can also be programmed to respond to changes in the process, such as changes in temperature or pressure, by adjusting the switches and relays accordingly.

Another advantage of using PLCs with switches and relays is that they can be remotely monitored and controlled. This allows operators to monitor the status of the process from a remote location and make adjustments as needed. This can be especially useful in applications where the process is taking place in a hazardous environment or in a remote location.

PLCs can also be used to improve the energy efficiency of industrial control systems. They can be programmed to turn off switches and relays when they are not needed, reducing the amount of energy that is consumed. This can result in significant cost savings for industrial facilities.

PLCs are a powerful tool for controlling switches and relays in industrial control systems. They can be programmed to perform specific tasks, respond to changes in the process, and be remotely monitored and controlled.

By using PLCs with switches and relays, industrial facilities can improve the efficiency and consistency of their processes and reduce energy costs. By optimizing the use of PLCs with switches and relays, businesses can achieve better performance, reduce costs and increase their competitiveness in the market.