“Revolutionising the wire & cable industry: Latest manufacturing advancements”

“Innovations revolutionizing wire & cable production: Efficiency, Quality, Sustainability” The new technology and innovations revolutionizing the way that wires and cables are produced. These advancements include automation, 3D printing, advanced materials, and sustainability. The latest trends and innovations in wire and cable production techniques and how they are improving efficiency, quality, and sustainability. One of […]

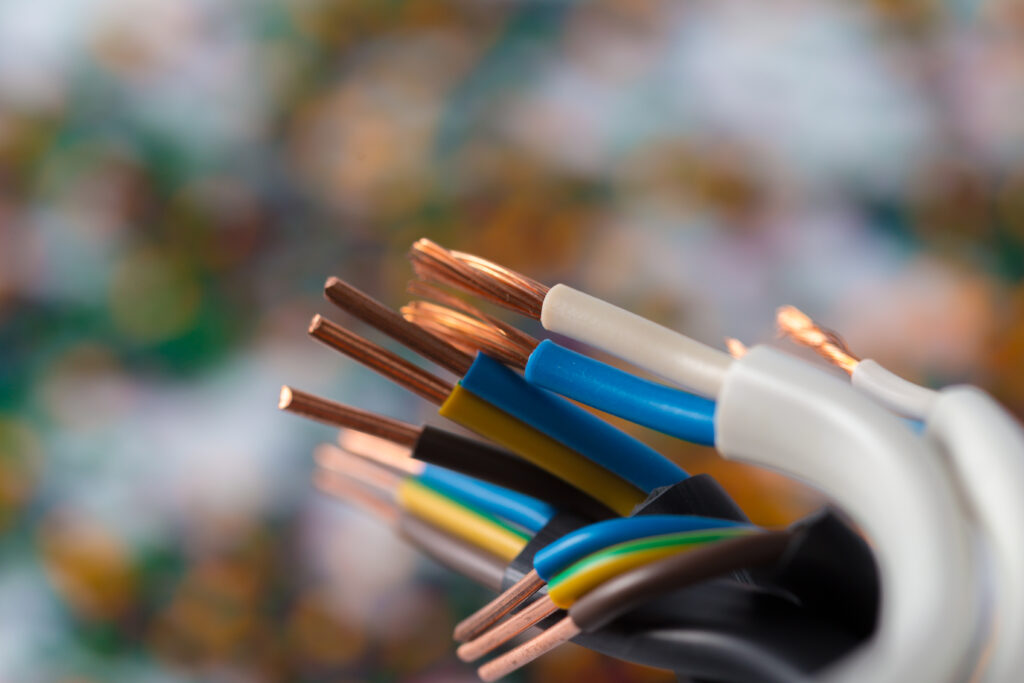

“Innovations revolutionizing wire & cable production: Efficiency, Quality, Sustainability”

The new technology and innovations revolutionizing the way that wires and cables are produced.

These advancements include automation, 3D printing, advanced materials, and sustainability.

The latest trends and innovations in wire and cable production techniques and how they are improving efficiency, quality, and sustainability.

One of the most significant advancements in the wire and cable manufacturing industry is automation. Automation systems are being used to improve efficiency, reduce labor costs, and increase the quality of the final product.

Automation systems can be used for a variety of processes such as wire drawing, stranding, and cabling.

These systems can also be integrated with other digital technologies, such as sensors and IoT devices, to improve the overall efficiency and accuracy of the manufacturing process.

Another important aspect of automation in the wire and cable industry is the use of robots. Robotics technology allows for the precise control of the manufacturing process and can also improve safety by reducing the need for manual labor.

Robotics technology can also be used to improve the accuracy of the manufacturing process, which can lead to a reduction in waste and an increase in quality.

Automation and digitalization in wires and cables

Automation and digitalization are transforming the way wires and cables are manufactured.

One of the most significant impacts of automation in the wire and cable industry is the increase in efficiency. Automation systems can be used to improve the speed and accuracy of various manufacturing processes such as wire drawing, stranding, and cabling.

This leads to a reduction in labor costs and an increase in production output.

Additionally, automation systems can be integrated with digital technologies such as sensors and IoT devices to further improve efficiency by monitoring and controlling the manufacturing process in real-time.

Robotics technology which is another important aspect of automation in the wire and cable industry. It allows for the precise control of the manufacturing process and can also improve safety by reducing the need for manual labor.

The technology can also be used to improve the accuracy of the manufacturing process, which can lead to a reduction in waste and an increase in quality.

Digitalisation is also having a significant impact on the wire and cable industry. The incorporation of digital technology such as advanced software, big data analytics, and cloud computing is leading to more efficient and effective manufacturing processes.

Advanced software can be used to optimize production schedules, improve inventory management, and reduce downtime. Additionally, big data analytics can be used to analyze production data and identify areas for improvement.

Internet of things (IoT) is also playing a major role in the digitalization of the wire and cable industry. IoT devices can be integrated into the manufacturing process to monitor and control the production in real-time.

This can lead to improved efficiency, quality, and sustainability by allowing for real-time monitoring and control of the manufacturing process.

The most important benefits of automation and digitalization in the wire and cable industry is the increase in sustainability. Automation systems can be used to improve the efficiency of the manufacturing process, which can lead to a reduction in energy consumption and waste.

Digitalisation can be used to optimize production schedules, improve inventory management, and reduce downtime, which can lead to a reduction in resource consumption.

Automation and digitalization are revolutionizing the wire and cable industry. The incorporation of advanced technology and automation systems is leading to increased efficiency, quality, and sustainability in the wire and cable manufacturing process.

The future of the wire and cable industry looks bright with the continued advancements in automation and digitalization technology.