Taiwanese PCB manufacturers shifting to Southeast Asia

Taiwanese PCB manufacturers relocate to Southeast Asia Taiwan’s printed circuit board (PCB) makers are moving their production to Southeast Asia to mitigate the impact of the trade war between the United States and China. The move is aimed at reducing their dependence on China and securing alternative supply chains. The shift in production is also […]

Taiwanese PCB manufacturers relocate to Southeast Asia

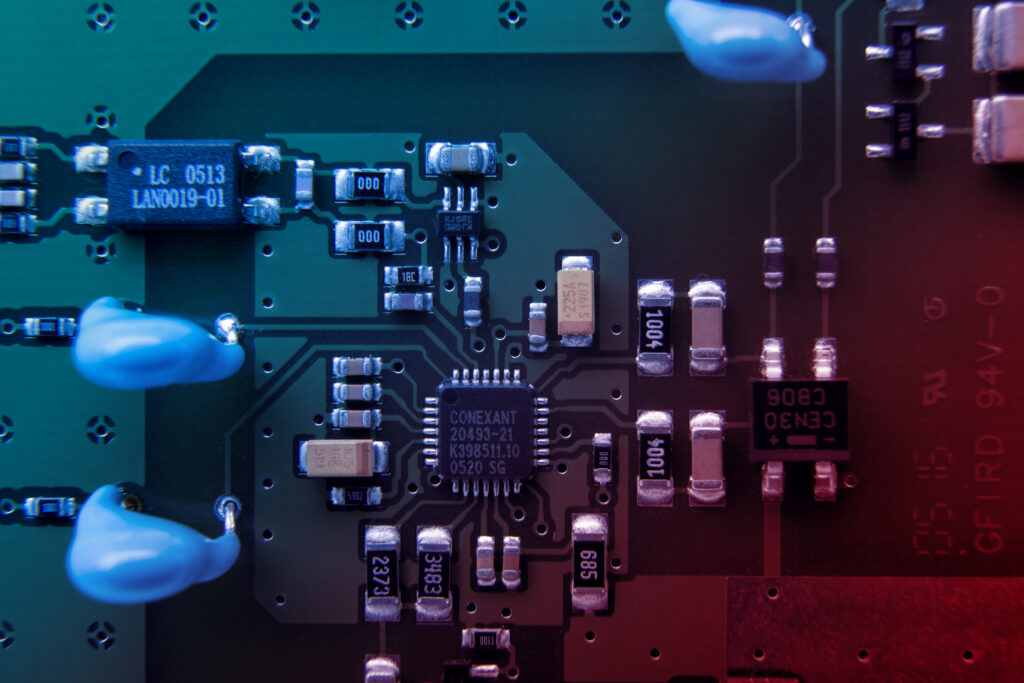

Taiwan’s printed circuit board (PCB) makers are moving their production to Southeast Asia to mitigate the impact of the trade war between the United States and China.

The move is aimed at reducing their dependence on China and securing alternative supply chains.

The shift in production is also driven by rising wages in China and the increasing cost of labor, land, and resources.

Southeast Asia is emerging as a top destination for Taiwan’s PCB makers due to its proximity, skilled workforce, and favorable investment policies. Vietnam, Thailand, and Malaysia are some of the most sought-after locations for these companies.

Vietnam has become a hub for electronics manufacturing in recent years, attracting investments from several multinational corporations.

The country’s favorable policies, low labor costs, and skilled workforce make it an ideal destination for Taiwan’s PCB makers. Major Taiwanese companies such as Foxconn, Pegatron, and Wistron have already set up their operations in Vietnam.

Similarly, Thailand’s booming electronics industry and favorable investment policies are attracting several Taiwanese companies.

The country is home to a large number of electronic component manufacturers, making it an ideal location for PCB makers.

Moreover, the Thai government’s commitment to promoting investment and creating a business-friendly environment has further boosted the country’s appeal.

Malaysia is another popular destination for Taiwan’s PCB makers. The country’s strong infrastructure, skilled workforce, and favorable investment policies have made it an attractive location for foreign investors.

Additionally, the Malaysian government’s efforts to promote high-tech industries and innovation have created a conducive environment for businesses to flourish.

The shift in production to Southeast Asia is not without its challenges, however. Companies need to invest in building new facilities, hiring and training new workers, and developing new supply chains.

Moreover, they need to navigate the complex regulatory environment in each country, which can be time-consuming and costly.

Despite these challenges, the benefits of moving production to Southeast Asia outweigh the costs for Taiwan’s PCB makers. The move will reduce their dependence on China, diversify their supply chains, and enable them to tap into new markets.

Additionally, the low labor costs and favorable investment policies in Southeast Asia will help them remain competitive in the global market.

The move to Southeast Asia also has broader implications for the electronics industry. It will increase competition in the region, which could lead to lower prices for consumers.

It will spur innovation and technological advancements, as companies invest in research and development to stay ahead of the competition.

Taiwan’s PCB makers are moving their production to Southeast Asia to mitigate the impact of the trade war and reduce their dependence on China. Vietnam, Thailand, and Malaysia are emerging as top destinations for these companies, thanks to their skilled workforce, favorable investment policies, and proximity.

While the shift in production is not without its challenges, it will enable Taiwan’s PCB makers to remain competitive in the global market, tap into new markets, and drive innovation in the electronics industry.